Casting Resins Systems from ebalta – High-performance polyurethane resins, epoxy resins and silicones

The ebalta product range of casting resins is flexible and individual. It contains high-quality casting resin systems for every requirement, including the necessary project support from prototype construction to the production of medium-sized series. ebalta casting resins are used in all industrial manufacturing sectors. For example, in the automotive industry, in mechanical engineering, in medical technology and everywhere where models, moulds, tools and parts made of plastic are required.

In addition to the variety of PU resins, epoxy resins and silicones, further plastics are constantly being developed. These also include ECO-friendly plastics in which renewable raw materials play a significant role. For example, ebalta also offers new developments for casting resins as carbon neutral products, where the CO2 footprint of the entire life cycle is reduced and offset.

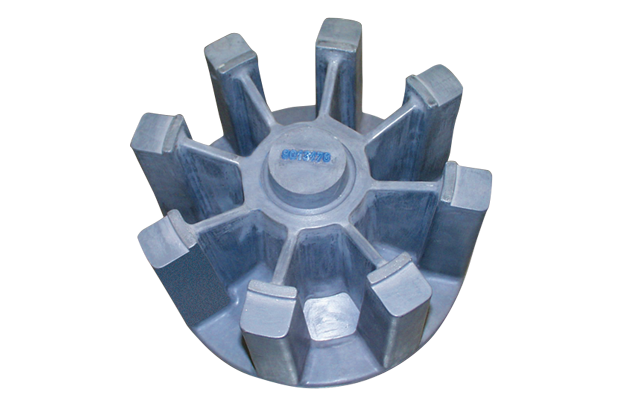

Flexible, sustainable, abrasion-resistant, flame-retardant: the demands on models, moulds, tools, parts and prototypes are very high. The polyurethane resins from ebalta counter this with a high-performance and sustainable product range of tooling cast resins, elastomer and resins for vacuum casting, resins for RIM, polyurethane casting foams, electrical encapsulation resins and climbing holds resins for the production and manufacturing of pilot, small and medium series.

Due to their nature, polyurethane resins are ideal for shorter product life cycles and development times. Examples of this are ebalta’s machine casting compounds for rapid prototyping, rapid tooling and series production. Similar to thermoplastic materials (rubber, PE, PP, ABS, PC etc.), they perform very well due to their geometric flexibility, temperature resistance and high E-module.

Epoxy resins are an essential material for lightweight construction in high-tech areas such as racing, boat building, the automotive industry, rail vehicle construction and wind power.

ebalta epoxy resins are two-component systems that cover a very wide range of applications: for mould and tool making – in addition to the ebaoard epoxy boards – modelling pastes, epoxy casting resins, gel coats and reinforcing pastes are offered.

Due to their high strength and high heat resistance, ebalta’s general-purpose and laminating resins are suitable for the production of composite parts, laminate moulds, backfillings or as binding resins for fillers. Due to the varied choice of hardeners, pot life can be optimally adjusted. The result: dense surfaces and stable components.

With ebalta silicones, complex virtual geometries are quickly produced into three-dimensional, tangible parts. Silicones have become essential for rapid prototyping and rapid tooling. The performance characteristics of ebalta moulding silicones are dimensional stability, reproduction accuracy, easy processing and good tear resistance. The extensive product range of rubber for moulds includes addition-curing and condensation-curing silicones.

To ensure that all process steps succeed, ebalta provides a complete range of ancillary materials and auxiliaries for the model, mould and tool making needs, as well as for the production of medium series. These include release agents, mould sealers, fillers, polyester putty, coupling pastes, colour pastes, fibre and carbon cloths, wax sheets, toiling gypsum and accessories matched to ebalta modelling and tooling boards, blocks and casting resins.